Q29: 25 Feb 2015: Were the post builders a little

tipsy or was the architect making a political

statement? The NW corner columns of the sixth,

seventh, and eighth floors are leaning right — or

inward. (Photo attached.) Why? Will the

occupants of those apartments be able to see

the Pisa Posts from the inside? Will outside

observers? No matter the explanation, those Pisa

Posts (Leaning Tower of) still look strange ;-)

That is a very expensive and painful result of the

building owners efforts to reduce the “mass” of

the building by changing the design to step back

the top floor. I could have paid for my home 3

times over for what those crooked columns cost.

They won’t be very visible when the building is

done but you may be able to notice them since

you know they are there.

Q28: 09 Feb 2015 - The Building Blog camera can

not see it, but while walking several block away

this morning, I realized there is an additional mini

"story" on the North side of the roof — some

structure with a roof on the roof. What is hiding

up there?

That is the "elevator head house" Every elevator

is required to have a refuge space above the car

at its highest elevation to prevent the service

technicians from being crushed in the event it

somehow is activated with them on the roof.

Sadly enough most of the odd rules such as this

one are a result of a lesson learned.

Q27: 09 Feb 2015 - For the last two weeks, a

steam shovel (alright backhoe, little digger,

whatever) has been huffing and puffing and

moving dirt along the Connecticut Ave. fence.

What is it doing?

That is commonly referred to as a mini excavator,

not exactly a mini. They are working on installing

the PEPCO electrical duct bank which will bring

electricity to the new building.

Q26: 26 Jan 2015 - So, is this what the elevator

buttons will show (roughly)?

Roof with swimming pool on South Side

Floor 9 (inhabited)

Floor 8 (inhabited)

Floor 7 (inhabited)

Floor 6 (inhabited)

Floor 5 (inhabited)

Floor 4 (inhabited)

Floor 3 (inhabited)

Floor 2 (inhabited)

Floor 1 (Main Entrance)(inhabited)

Cellar / Basement (inhabited)

Parking 1

Parking 2

Ten floors of residence, two of parking and a

usable roof with a pool? What will be on the

north side roof?

- Pretty much. The cellar level doesn’t have very

many units, some common area amenities and

storage. The roof is accessible however the

majority of it is mechanical space with some

amenity space like a small space to walk a dog

and some chairs to enjoy the outdoors and a small

pool. I have no idea what the rents will be. You

should stat seeing the window systems being

installed now.

Q25: 28 Dec 2014 - It looks like shrink-wrapped

pallets of materials have been placed in each

apartment. What is inside - kitchen cabinets,

plumbing fixtures, air handlers? Leigh

The shrink wrapped crates your seeing are the

windows which are about to be installed. I can't

bring in the cabinetry until the building is weather

tight and has some climate control, wood and

wood like product don't react well to high levels of

humidity.

Q24: Please confirm the levels and their

purposes.

- At the very bottom of the site is level one,

which is parking, and level two which is parking.

- Then comes that schizophrenic level, level three,

which Rob called the cellar and the Building Blog

has been calling the ground floor; when driving in

from the gate, the road leads into the building

level three.

- The fourth level is the first floor, which is the

pedestrian entrance for the building.

- And the fifth level is the second floor of the

building.

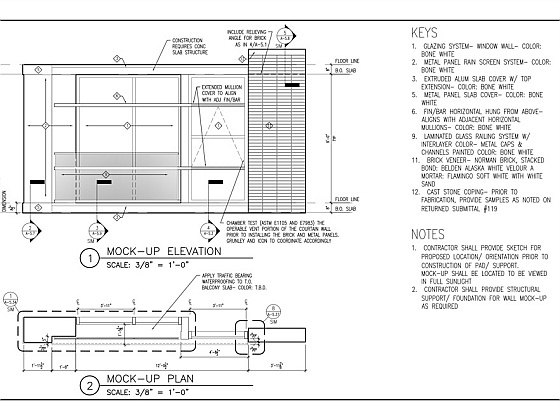

Q23: 11 July 2014 - What on earth is the full

cement wall going up almost ON Connecticut

Ave? Is that really the outline of the building

itself?

What you see being build on the corner is a full

scale mockup of a section of the building

complete with masonry, glass and railings. We use

these to establish quality control standards for

each component so that everyone understands

what is being build and how. When the mock up is

complete you will get a glimpse of what a portion

of the building will look like then after it is all done

and the team reviews it we tear it down. I have

attached a PDF copy of the drawing being used to

construct it. [

Q22: 04 July 2014 - Interested as to how you and

the architects cooperate with the details of a

tremendous project of this nature. Very

impressed! Chet McCabe

Communication is always the key to success

in any venture and in construction a failed project

is always suffering from a lack of it. On the

majority of the projects that I have been a part of

the Architect and engineers along with the

contractor and owner all work together as a

project team towards a common goal of

construction the building safely, correctly, on time

and on budget as delays and changes only cost

everyone time and money.

When it comes to formal communication

there is a formal process used to not only

disseminate the information but to track it and it

is called the Request For Information or RFI. This is

where anyone on the project team can ask for

additional information or clarification of any detail

or drawing. As you might imagine there are times

when differing drawings don't match exactly and

any time that happens we ask for clarification.

The process is very limited to clarifications only as

any significant changes have to be processed in a

different manner called an addendum. Even in

cases such as those the changes are not typically

something that modifies the exterior of the

building but are limited to interior changes or

modifications. As you know exterior changes are

required to go through a long approval process

involving the authorities having jurisdiction and

once a project starts there is normally not enough

time to accommodate that process.

In addition to this there is a constant less

formal flow of verbal and electronic

communication along with regular on site team

project meetings and site visits by the designers.

On site there are also progress meetings held

every week with the subcontractors where safety,

schedule and issues are discussed in detail and

when the occasion merits the design team is

engaged as well. Also present throughout the

project are independent inspectors who regularly

check the installations and products being used

issuing reports to the owner and coping the

construction team. These are a tremendous asset

and augment our own quality control inspections

helping the entire team to deliver a quality

project. Lastly there are regular inspections by

the Authorities Having Jurisdiction such as the

Building Inspectors who will contact the project

team if they find something that is not

conforming to the approved plans which are

stamped by the City during the permitting

process.

Q21: 30 Jun 2014 - What is the name and purpose

of the Concrete Zamboni? Looks like fun -- from

inside an air conditioned house.

The Zamboni is a ride-on power trowel that

smooths the concrete in stages as it hardens.

They are quite a handful if there are a number of

things sticking up out of the slab but are sort of

fun to drive.

Q20: 30 Jun 2014 - Into the freshly poured

cement, a crew member pushed a wand, as if to

stir the cement mixture. What and why?

The wand has a laser detector that gives a

audible tone when the proper grade is achieved.

This is how we get the floors flat and level.

Q19: 27Jun 2014 - Are the gang forms that hold

the cement removed after the cement is dry and

reused or do they become part of the cement

structure?

The vast majority of the formwork you see is part

of a system that is reused many, many times. In

special case where custom fitting is required the

crew hand fits sections of plywood formwork

which is also reused to the point where the pieces,

after being cut so many times become unusable.

Everything that goes into the dumpsters here is

then hauled to a sorting facility where it is almost

all recycled.

Q18: 27Jun 2014 - On the ground floor (third

deck) what are the blue "spaghetti" cables that

are now strung like two guitars?

Those are called post tension cables. After the

concrete slab is placed and cures to the point of

reaching the design strength the installers attach

a pulling device to each cable and pull them

taught to the intended tension. This is one

method of reducing the depth of the floor

construction and lowering costs, very typical here

in DC. I have attached a photo of two of the men

installing them.

Q17: 19 June 2014 - What happens if you can't

build something the way the architect planned

it?

That is fairly uncommon, there are always a

multitude of questions during the process but for

the most part they are clarification questions. In

instances where something simply doesn't work

we do not proceed until the issues are discussed

and resolved by the designers with documentation

issued. Exterior changes almost never happen and

always involve the authority having jurisdiction in

the approval process which is the main reason

they rarely occur.

Q16: 19 June 2014 - Will any of the apartments be

more than one level, i.e. two stories or split-

level?

None of the units are more than one story, they

do vary in size and shape.

Q15: 19 June 2014 - When will we see the

footprint of the building? We understand it will

be set back with a circular drive on Connecticut.

The actual building footprint will become visible

after the first floor level deck is placed, that is the

level that is roughly even with Connecticut Ave,

below Kanawha and one level up from what we

currently have placed. The circular drive has not

made it to the construction team yet.

Q14: 19 June 2014 - Where is the hole for the

elevator? Do you build around the elevator shaft

or is it cut at a later date by a different crew?

Right now it is a little difficult to tell where the

elevators are. There is a three sided concrete

shaft nearest the construction gate that is the

single cab elevator which runs from the P1

parking level up (P2 being the lower level

parking). Mid way up the building in the ramp

section there is a double car elevator pit that the

crew currently has decked over to serve as a

temporary loading platform for the P2 level.

Q13: 19 June 2014 - Will the foundation of all the

levels be cement or will the floors of the upper

levels of the building have a different

construction?

With the building height restrictions in this city

the most economical structure is post tension

concrete. This enables the structural slabs to be

thinner than other types of construction and that

is what the first floor and above is designed to be.

The parking decks are structural elevated slabs

relying on rebar and concrete without post tension

cables.

Q12: 19 June 2014 - This ground floor seems

different than the other two floors. Is it taking

more time?

That one in particular is very complicated with an

inordinate amount of elevation changes to

accommodate the exterior courtyards and it is

significantly larger than the upper level floors. The

building footprint will dramatically shrink at the

first floor level.

Q11: 19 June 2014 - About how long does it take

to complete one "floor"?

Generally all buildings of this type take a little

longer getting up above grade than what is

typical for upper level floors. The cycle is roughly

three weeks a floor however what you will see is a

continuation of what is here now with multiple

floors under construction at any given time.

Q10: 14 April, 2014 - What are the red forms, the

big yellow, box, and the gray box with the

wooden exoskeleton.

The red forms are part of the concrete wall

forming system called gang forms. The big yellow

box is a diesel electric generator needed to power

the tower crane which is electric powered. The

gray box is a shipping container used to store

tools and materials. The crew erected a safety

railing around the top of it as they are using the

roof to store ladders, we have a fairly tight site

and need to maximize every square foot

Q9: Yesterday 07 Apr 2014, in the middle of the

site, there appeared an opening to a very deep,

square hole. Have you unearthed the Gates to

Hades?

Hades? That would certainly be interesting but

no. The large square excavations you see are

spread footings which the columns are built on.

The civil and geotechnical engineers determine

the bearing capacity of the soils early on in the

design by test drilling and sampling the soils. From

there the structural engineer, using the design

given to them by the architect locates the interior

columns then using dead load on each column

determines how large the footing needs to be in

order to support the column. Some footings are

substantially larger than others, the largest so far

took 6 concrete mixers ti fill, over 500 cubic

yards.

Q8: 08 Apr 2014 - At the 5333 Connecticut Ave

site, have you found any archeological remnants

of an earlier era?"

Honestly the site was very clean, we found only

modern day items like concrete and a shopping

cart on the surface. Whoever removed the homes

that were here did a thorough job and left the site

in good condition. While excavating we have found

some quartz, which I also see in the stone walls in

the neighborhood. The soils are relatively well

draining and what we consider to be good fill

material.

Q7: 07 Apr 2014 from Marc: When completed?

How many units? Condos or rental? In addition

how long will the general contractor be involved

in the building?

Provided the weather is cooperative, by the end

of next summer we should be done with 261

rental units. We will perform all of the construction

including landscaping, finish carpentry and wall

paper.

Q6: How far down are you digging?

A: From the Military side we are a little over 20

feet deep and just over 40 on the Kanawha side.

Your soils here are quite good and drain well,

somewhat high in mica which makes the ground

glimmer in the light. We are at the final depth now

and just tipping the top of the water table which

is perfect, digging below the water table is no fun

at all and is just an all-around miserable mess.

Q5: The site tower is as fascinating as it is large.

A: The Tower Crane is a Terex Peiner SK415 made

in Germany at a cost of just under a million dollars

and measures 214’-4” from the top of the base

foundation (280’ above sea level) to the very tip

of the rigging above the cab. The boom of the

crane is 180’-4” and it has a maximum lifting

capacity (which we will not be lifting) of 20 tons

without special rigging. The reason for the heavy

duty capacity is actually the reach as we have

only the alley for access which make this project

a little like building a ship in a bottle.

Q4: Does the concrete funnel hoisted by the

crane have a special name?

A. The concrete funnel or cone is simply called a

concrete bucket, no fancy terminology for this.

We have several sizes with the largest having a

four cubic yard capacity which we only use when

the trucks back up close to the crane. The larger

buckets are made of solid aluminum to cut down

the weight which is always good, with the smaller

ones made of steel.

Q3: What are the names of some of the larger

equipment. The horizontal-hole-poking-machine

that drills holes into the retaining walls must

have a better name than the one we gave it.

A: The horizontal hole poking machine (absolutely

hilarious, love it) is actually an Ingersoll Rand rock

drill commonly used for drilling rock. The operator

was from Ontario Canada and was trained at a

specialty college in Canada to operate specialized

drilling equipment, a nice young fellow who was

glad to be here for the “warm winters.” The Mini

bulldozer is called a skidsteer, they are a blast to

operate. The large orange machine is a mid-sized

excavator, one of three excavators we have here

now and the large yellow machine with tank

tracks is called a shovel dozer or track loader by

the men.

Q2: Subcontractors?

A: The concrete subcontractor is Baker DC as you

can probably see from the sign up on the crane.

Many of them here are from Ohio where work is

slow right now, thus far they are doing a fantastic

job.

Q1: Chevy Chase DC hasn't seen construction

this significant in a decade. The Construction

process is different and exciting to our

neighborhood, but is must be just everyday to

you and your crew.

A: I’ve been building large projects for many

years at this point and have worked in Maine, New

Hampshire, Massachusetts, Virginia and DC and

can honestly say each is very different and has

presented unique challenges. I have built

numerous schools, Universities and healthcare

facilities in residential areas and each created

some fairly significant shock as the rambunctious

construction process began. I have found that

after a short time our presence becomes part of

the daily norm and as long as we try hard to be

considerate the vast majority of the residents get

used to us and some become part of the routine

asking questions and waving hello.